Very light weight bullets normally lose balance and alignment, and are not accurate. But you can make normal length bullets with very light weights, and shift the balance forward to regain accuracy. For example, the technique has been used to make 70 grain .38 Specials that could achieve nearly 2,000 fps accurately from a 4-inch barrel revolver.

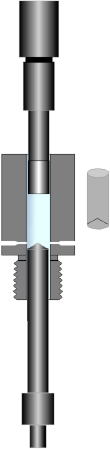

Lighter weight jacketed bullets can be made in the same length jacket by putting a polymer "bullet ball" in the bottom of the jacket. This takes up some of the space in the jacket, so you can use a lighter (shorter) core on top of it. There is an advantage in shifting the weight forward, so that less spin rate is required for the same length. Standard or slower twist barrels often can shoot a long, light bullet accurately, using this balance-shifting technique. Corbin provides linear polyethylene "bullet balls" in various diameters and colors, in packages of 1000.

Very light weight bullets normally lose balance and alignment, and are not accurate. But you can make normal length bullets with very light weights, and shift the balance forward to regain accuracy. For example, the technique has been used to make 70 grain .38 Specials that could achieve nearly 2,000 fps accurately from a 4-inch barrel revolver.

Lighter weight jacketed bullets can be made in the same length jacket by putting a polymer "bullet ball" in the bottom of the jacket. This takes up some of the space in the jacket, so you can use a lighter (shorter) core on top of it. There is an advantage in shifting the weight forward, so that less spin rate is required for the same length. Standard or slower twist barrels often can shoot a long, light bullet accurately, using this balance-shifting technique. Corbin provides linear polyethylene "bullet balls" in various diameters and colors, in packages of 1000.

Normally, the core seating punch that comes with a core seat die is made to fit properly near the jacket mouth. As you seat the core deeper, the jacket walls become thicker, so the punch needs to be smaller in diameter. Putting the plastic ball in the base of the jacket brings a short lead core closer to the tip, so the normal diameter punch probably will be fine. However, there is one possible problem: the lead core probably won't squash the poly ball flat, but may make it flow off to one side before the lead comes to rest. Centering the ball exactly is important. How is it done?

One way to center the ball is to use a core that is formed with a conical "center hole" depression in one end. When such a core is placed in the jacket, the ball is automatically directed to the exact center of the core. When the core is seated, it has no choice but to flow evenly around the ball, keeping it precisely centered. The conical cavity is formed by requesting a 45-degree "center punch" shaped tip on one of the core swage punches (the punch the fits the CSW-1 core swage die). The best punch for this is the internal punch, because the external punch might be moved off to one side when you attempt to push the core into the die, if the core is cut with a slight angle to the end.

One way to center the ball is to use a core that is formed with a conical "center hole" depression in one end. When such a core is placed in the jacket, the ball is automatically directed to the exact center of the core. When the core is seated, it has no choice but to flow evenly around the ball, keeping it precisely centered. The conical cavity is formed by requesting a 45-degree "center punch" shaped tip on one of the core swage punches (the punch the fits the CSW-1 core swage die). The best punch for this is the internal punch, because the external punch might be moved off to one side when you attempt to push the core into the die, if the core is cut with a slight angle to the end.

So, what do you need in order to make a longer, lighter bullet? Here's a checklist:

So, what do you need in order to make a longer, lighter bullet? Here's a checklist:

- Your regular swage dies plus...

- PUNCH-S or PUNCH-H, Internal CSW, 45-deg.tip

- BULLET BALLS (such as BB-1/4 for .308)

If the seated core will come to normal height in the jacket, your regular external core seating punch should fit the same as always. Remember that whenever you want to seat a short core deep inside a tapered-wall jacket, the core seating punch must be small enough to fit the jacket ID at that depth, and long enough to reach that far into the jacket.

Another possible issue is the minimum length of core that your particular core swage die and punch will handle. Most core swages can make very short, light cores IF you equip them with the proper internal punch. The head of the internal punch positions the punch within the ram, so that the end of the punch (inside the die) comes to a normal depth for regular cores. You have some range of adjustment with the external punch.

Another possible issue is the minimum length of core that your particular core swage die and punch will handle. Most core swages can make very short, light cores IF you equip them with the proper internal punch. The head of the internal punch positions the punch within the ram, so that the end of the punch (inside the die) comes to a normal depth for regular cores. You have some range of adjustment with the external punch.

But when the core becomes too short (light), the external punch may have to reach so far down into the die that it either blocks the bleed holes, or it runs out of length. A different internal punch with longer head will position the end of the punch closer to the die mouth, and allow the use of your normal external punch. Alternatively, the external punch could be made longer, depending on where the bleed holes are located. If the bleed holes are already being covered by the external punch, then making it longer won't help.

But when the core becomes too short (light), the external punch may have to reach so far down into the die that it either blocks the bleed holes, or it runs out of length. A different internal punch with longer head will position the end of the punch closer to the die mouth, and allow the use of your normal external punch. Alternatively, the external punch could be made longer, depending on where the bleed holes are located. If the bleed holes are already being covered by the external punch, then making it longer won't help.

Depending on the purpose of the die and its usual range of core lengths, the bleed holes may be located near the bottom or closer to the middle of the die length. It is easy to tell where the punch tip comes by laying out the die, core, and punch on the table beside each other. If the punch tip has not covered the bleed hole location, then a longer external punch would work. Otherwise, a longer head on the internal punch is the correct solution to making lighter cores.

Depending on the purpose of the die and its usual range of core lengths, the bleed holes may be located near the bottom or closer to the middle of the die length. It is easy to tell where the punch tip comes by laying out the die, core, and punch on the table beside each other. If the punch tip has not covered the bleed hole location, then a longer external punch would work. Otherwise, a longer head on the internal punch is the correct solution to making lighter cores.

With non-jacketed (lead) bullets, a longer bullet can be created with a light weight core by using a large hollow point, a large hollow base, or a combination of the two. Sometimes the difference between a hollow base and a flat base can make ten or fifteen percent difference in the bullet length. The BC of a bullet is increased by heavier weight for the same diameter, or smaller diameter for the same weight, but how the weight is distributed in the same diameter is not addressed in the typical BC formula. In short, making the bullet longer by adding hollow cavity space to keep the same weight has no affect on BC by itself. The stability of the bullet (and require spin rate) can be affected by the distribution of weight, which is in control of the bullet maker.

Another way to make lighter bullets is to use powdered copper instead of lead for the core. Copper has a density about 2/3 that of lead, so the same length of bullet will be lighter with a copper core. A light weight bullet will also be longer, in the same caliber, if you use powdered copper in the jacket (or form the entire bullet of powdered copper, assuming you can use a non-expanding or fragmenting bullet design).

Corbin's atomized copper powder is available in 8 ounce and 64 ounce containers, as well as larger quantity packaging. The grains are coated with a thin layer of lithium stearate, which helps them pack together more closely by lowering the compression friction, and also helps them pour smoothly from a dispenser or through the powder funnel into a die or jacket. Copper powder is safe to swage into core seating dies, but will simply blow through the holes in a core swage. It is weighed using a dipper, powder measure, or scale, rather than swaged to weight.