Swage Die Terminology

Before you can understand what tools you need, you need to know what they are called!

|

|

If you don't know a die from a punch, or understand how bullet makers use terms like "hollow point" versus "open tip", it creates at least two major problems:

|

- You may not understand the instructions,

...and...

- You may order things you don't really want!

|

We sometimes get orders from people who don't bother to learn the terminology of swaging, and it creates delays, errors, and misunderstandings that don't happen when the right word is used. If you understand that the die is the cylinder that holds the pressure to form a bullet, and it has an internal punch (which slides up and down within the die to eject the bullet) and an external punch (which pushes the components into the die to swage them, then is retracted from the die to allow ejection), you won't be trying to order a "die punch" or a "punch die" or a "rod" or a "piston" or a "ram" or a "thing-a-ma-bob". You'll order the internal punch you actually want, and get it, instead of getting messages and phone calls trying to figure out what you mean.

So, while it's no problem to toss words around in casual conversation even if the meanings are just "sort of understood", it is really to your benefit to use the right terms when ordering, communicating, and working in a specific technical field like bullet swaging. The words are more precisely defined, because a little difference like "open tip" versus "hollow point" can make a HUGE difference in the required equipment and techniques used.

In Corbin's bullet swaging systems, there are FOUR general categories of swaging dies and punches:

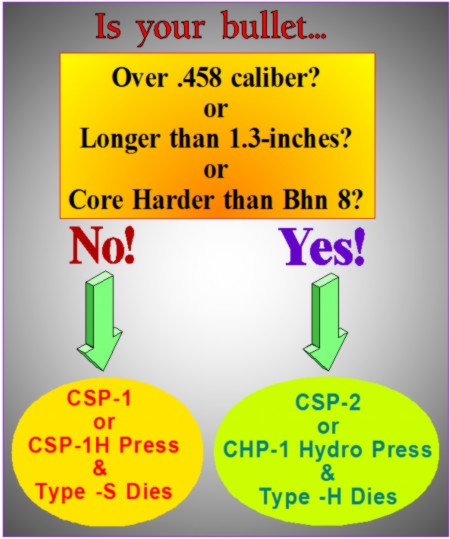

- Type -R dies and punches: These are used in Reloading presses, hence the "-R" at the end of the catalog number. Type -R dies have external punches which fit the T-slotted ram, and use a 7/8-14 adapter body to screw into the press head. To eject, you tap a knock-out rod in the die and catch the bullet with your other hand as it ejects downward from the die.

- Type -M dies and punches: These are early, discontinued tools for the old Mity Mite press (hence the "-M" designation) and its successors using 3/4-inch OD dies. They work in the first Corbin presses (Mity Mite, Silver Press), built decades ago. We still make them on special order today, and they

also work in the modern -S type presses we build now (with certain modifications or changes to internal punches for point form dies). These dies and punches work exactly like the -S type, described next...(except they have a slightly shorter maximum bullet length).

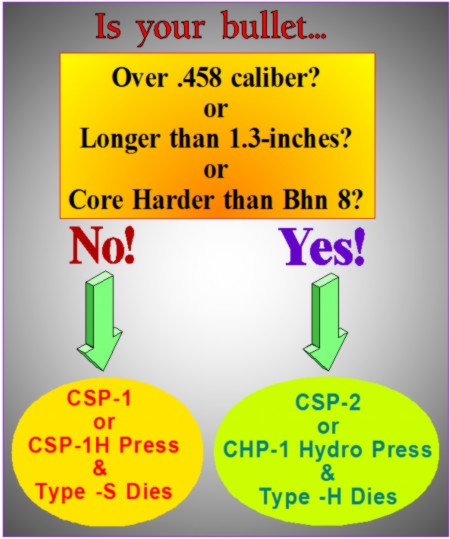

- Type -S dies and punches: These are the main tools for swaging in the range of .10 to .458 diameter bullets in the modern Corbin -S press. The discontinued Series II and the current S-Press use these dies. The "-S" designation originally meant "Steel" because the Series II press was all steel. It also means "Small" compared to the type -H, described next. They have a 1.3-inch maximum bullet length. The external punch fits into a punch holder in the press head. The die and internal punch screw into the press ram, and automatically eject on the down stroke. You simply run the ram of the press UP to swage, and run it DOWN to eject. The bullet rises out of the ram-mounted die, and sits atop the die for you to pick up (about 3 times faster to use than a reloading press system). The -S dies have 5/8-24 threaded tenons on the 1-inch diameter dies. This fits into the press ram.

- Type -H dies and punches: These dies and punches fit the -H type presses, which includes the Mega Mite, the Hydro Press, and the Hydro Junior. The "-H" in the catalog designation means "Hydraulic", even though we make a big (70-lb!) hand press to operate them as well as hydraulic pressses. Just like the -S type, these dies screw into the press ram along with the internal punch, and automatically eject on the down stroke. The external punch is held in a punch holder in the press head. Type -H dies usually have a 1.5 inch body with a 1 inch tenon (threaded for 1 x 12 tpi). They can have larger bodies as needed for special higher pressure operations, such as 2 or 2.5 inches. In all cases, they use a 1-inch threaded tenon to fit the press ram.

Catalog Numbers for Corbin Dies

The catalog number of each "set" of dies is an abbreviation that describes what that set can make. A "set" of dies can be from one to six dies. You never use more than five of the dies for a given design of bullet, but you might use a different group of five dies depending on the bullet style.

All the sets of dies are made up of combinations of individual dies you can buy separately. There is no price penalty for buying your sets a few dies at a time. You can start with a simple flat base open tip 3-die set, and add lead a lead tip die later. It costs the same as buying a 4-die set that includes the lead tip (LT) die.

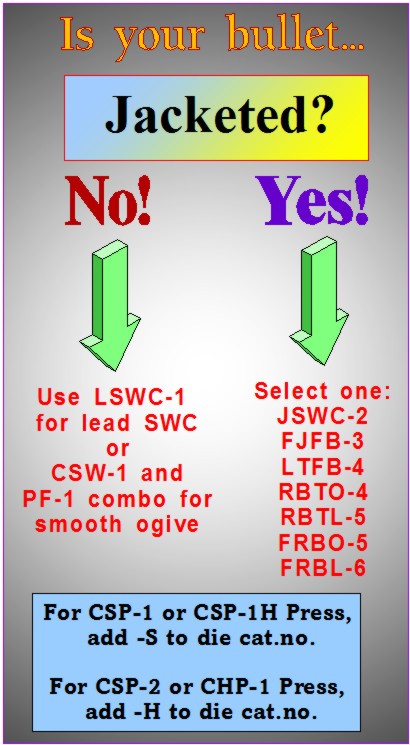

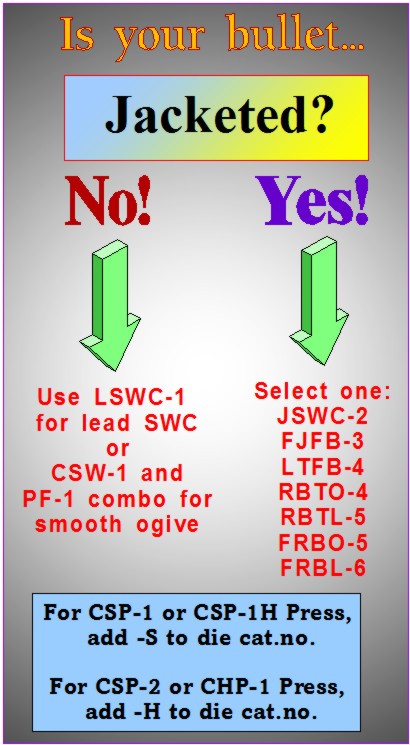

All sets of two or more dies start with a "Core Swage" or CSW-1 die. Core swaging is the act of forming the lead core to precise weight and shape before you use it in a jacket or shape it into a lead bullet. The core swage die has bleed holes that let you "squirt" surplus lead through them. (In the "old days" of swaging, some people called this a "squirt die".) If you make a lead bullet without a jacket, you may be able to form it in a single "LSWC-1" or Lead Semi-Wadcutter die.

The term "Semi-Wadcutter" just means that a punch forms the nose, and leaves a small "shoulder" where the nose stops and the "shank" or parallel part of the bullet body starts. It does NOT mean a specific nose shape (other than the requirement that there is a shoulder formed by the edge of the punch). You can have round nose, Keith nose, conical nose, even full wadcutter nose shapes and they are ALL made in a LSWC-1 die (if you use no jacket).

To make a bullet with a smooth curve from the ogive or nose to the shank, without a shoulder, you need to use a PF-1 point forming die and possibly a core seater or other preliminary steps in other dies. This is explained in detail at FJFB-3.HTM if you want to click it and jump ahead now. Or read on to become more enlightened about swaging!

|

CSW-1-

|

Core Swage Die

|

This is the die which adjusts the lead weight, and turns a piece of cut lead wire or cast lead core into a precise cylinder of the correct diameter, with flat ends. The CSW die is seldom used by itself, but is followed by the CS or PF (or both).

|

Click for instructions

|

|

CS-1-

|

Core Seat Die

|

This die presses the lead core into the jacket and forms the precise bullet shank. The core seater can also produce a finished jacketed semi-wadcutter bullet

or lead semi-wadcutter bullet, by using a nose punch having the desired cavity shape. However, the bullet will be about 0.0002-inches undersized compared to using a LSWC or PF die.

|

Click for instructions

|

|

PRO-1-R

|

Pro-Swage

|

The PRO-SWAGE is a special form of the CS die which is built for use on reloading presses only, and finishes the bullet in one stroke. It is used only with soft lead and may or may not use a jacket depending on the caliber. Only SWC-style noses can be made. These are all type -R prefix since they operate in a reloading press. Example: PRO-1-R (specify caliber, nose, base shape).

|

Click for instructions

|

|

PF-1-

|

Point Form Die

|

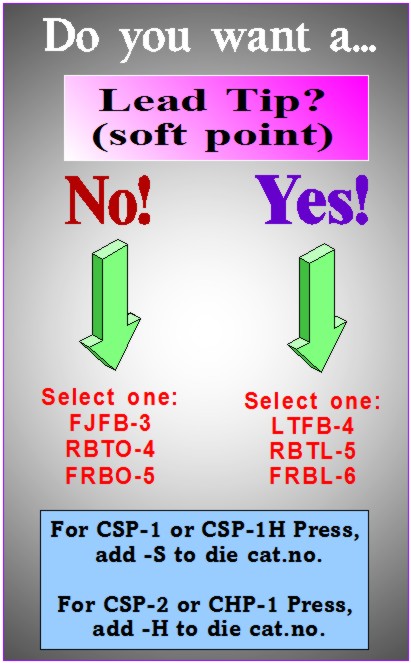

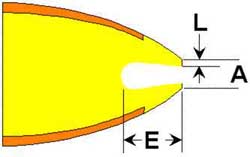

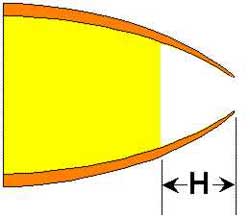

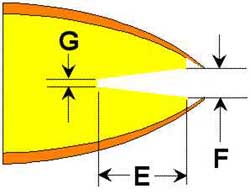

The Point Form Die or Point Former shapes the ogive curve on the bullet. If you want a bullet that does NOT have a step or shoulder between the shank and nose, you must use one of these dies to create it. Forming the nose in a punch cavity always leaves a shoulder (the edge of the punch), which we refer to as the Semi-Wadcutter shoulder. The point form die is always used with a matching CS die for jacketed bullets, and usually with a CSW die for lead bullets

|

Click for instructions

|

|

LT-1-

|

Lead Tip Die

|

The Lead Tip Forming die reshapes a lead tip bullet made in the point former to remove the distortion produced by ejecting the bullet from the point former die. It is never used without the PF die. The PF die comes first, then the LT die is an option if you want factory-finished lead tips, especially in sharper rifle nose shapes (many blunt or round nosed shapes look OK without using the LT die to clean them up).

|

Click for instructions

|

|

RBT-2-

|

Rebated Boattail Set

|

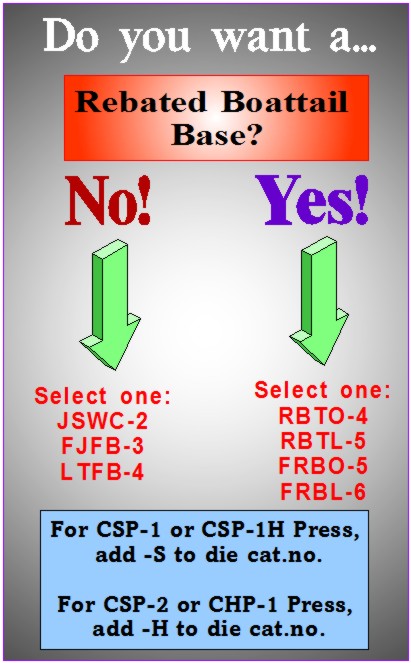

The dies to produce rebated boattails are the BT-1 and BT-2 dies. These are used as a set, INSTEAD of the usual CS die, to seat the lead core. The jacket and core are put into the BT-1 die and pressure is applied to the core with a punch, expanding the jacket and also forming a conventional angled boattail on the base. Then the assembly is ejected and put into the BT-2 die, where the angled base slides past a shoulder or rebate shape. Pressure is applied again, expanding the base section perfectly into the rebate shoulder and producing a gas sealing, muzzle blast deflecting shoulder that adds about 15% to the tightness of the group (compared to a conventional BT bullet). The RBT dies always come as a set of two, called the RBT-2.

|

Click for instructions

|

|

LSWC-1-

|

Lead Semi-Wadcutter die

|

The LSWC die combines the bleed holes of the CSW core swage with the nose and base shape punches and the final diameter of the bullet, to produce lead, gas checked, or base guard bullets in a single step. This die cannot produce a smooth ogive bullet: it must produce a semi-wadcutter style that has a small shoulder between nose and shank. It is very popular for paper patch rifle and base guard pistol bullets. It is used by itself, not as part of a set.

|

Click for instructions

|

|

DDS-1-

|

Dual Diameter Sizer die

|

The DDS-1 die takes a finished bullet and reduces the forward portion so it rides atop the lands, guiding the bullet without engraving it. The rear portion of the bullet is left full size so it engages the rifling, like an artillery shell. DDS dies are always used with a finished bullet. They do not make bullets by themselves. They can be used with jacketed or lead bullets. For special purposes, the base is pushed into the die first (making heel base bullets). The die is ordered with a specified nose shape and both diameters. For a spitzer .308, you might order the DDS with as a "6-S ogive, 308 to 300".

|

Click for instructions

|

|

JRD-1-.

|

Jacket Reducing Die

|

You would push an existing jacket through this die and out the top to make it smaller and longer. This is used with copper tubing jacket makers to produce the right diameter of jacket from stock tubing sizes, or to reduce certain cartridge cases and make them into "free" jackets, as well as to convert a commonly available jacket diameter into a smaller, longer size.

|

Click for instructions

|

|

BRD-1-

|

Bullet Reducing Die

|

You would push an existing bullet up through this die and out the top to make it slightly smaller in diameter. The maximum reduction that still gives you a good bullet is about .006 inches. You can turn .357 into 9mm easily. Another common use is to turn a .323 8mm into a .318 8mm. But you cannot turn a .429 (44) into a .410 (41) without destroying the accuracy. The BRD is also called a "bullet draw die".

|

Click for instructions

|

|

CTJM-1-

|

Copper Tubing Jacket Maker

|

This is a set of dies and punches forms ordinary copper tubing into excellent hunting quality bullet jackets, rolling the end over to form a base and then flattening it. It requires the use of a core seating die from a regular bullet swage die set to finish forming the closed base. Copper tubing is the most practical way to make certain large rifle calibers without using coiled strip.

|

Click for instructions

|

|

BGK-1-

|

Base Guard Kit

|

This is a die to punch out a Base Guard disk from strip copper. You normally use .030 thick copper strip, usually 1/2-inch wide. The base guard attaches to a lead bullet base during swaging, when you use a special BG base punch. It scrapes the fouling and leading out of your barrel with every shot you take, eliminating the need for lubricant or hard lead.

|

Click for instructions

|

|

SDD-1-.

|

Serrate/Draw Die

|

This is a die that puts shallow grooves along the axis of a bullet or jacket, so it will open up along these weakened areas on impact. SDD-1- type dies can be made to serrate before or after a bullet is made, or serrate the entire jacket length from tip to base. The SDD-2- type dies allow partial insertion and ejection of the jacket, so that the ogive section can be serrated before it is formed into a curved bullet nose.

|

Click for instructions

|

|

Punches

Click a picture for information about standard and special punch types for type -R, -S, and -H die sets. The punches are the "rods" that move inside the dies. They seal the pressure within the die. The internal punch stays inside the die and moves toward the die mouth to eject the component or bullet. The external punch separates from the die on each stroke of the press, to allow insertion of another component and to make room for ejection. Please do not call a die a punch, or vice versa, as it will be very confusing and your orders will often be wrong. Ordering a "die-punch" also makes no sense to us, because either you want a die (the cylinder that holds the pressure) or a punch (the piston or rod that fits into the die), or perhaps you want the complete "die set" which is the die with its associated punches. If you want a punch, you will want either an external punch, or an internal punchl. Usually we can tell by the context, but it helps if you learn the difference and order what you really want.

Click a picture for information about standard and special punch types for type -R, -S, and -H die sets. The punches are the "rods" that move inside the dies. They seal the pressure within the die. The internal punch stays inside the die and moves toward the die mouth to eject the component or bullet. The external punch separates from the die on each stroke of the press, to allow insertion of another component and to make room for ejection. Please do not call a die a punch, or vice versa, as it will be very confusing and your orders will often be wrong. Ordering a "die-punch" also makes no sense to us, because either you want a die (the cylinder that holds the pressure) or a punch (the piston or rod that fits into the die), or perhaps you want the complete "die set" which is the die with its associated punches. If you want a punch, you will want either an external punch, or an internal punchl. Usually we can tell by the context, but it helps if you learn the difference and order what you really want.

|

|

DIE SYSTEMS (-R, -M, -S, -H)

In each of the catalog numbers, you will see a letter designation, followed by a dash and a number. The number refers to the quantity of individual dies that are in the set, or in a few cases refers to a special variation on the set. The individual dies for swaging are combined into matching sets to build certain kinds of bullets. All dies and punches are made to fit a certain "system", refering to the press into which they are installed for operation:

|

-R

|

Reloading Press

|

7/8-14 die fits press head, button shell holder on external punch fits ram.

|

|

-S

|

Corbin CSP-1 S-Press

Corbin CSP-1H HydroMite

|

5/8-24 die fits ram, external punch fits FPH-1-S floating punch holder in press head

|

|

-H

|

Corbin CHP-1 Hydro-Press

Corbin CSP-2 Mega-Mite

Corbin CSP-2H Hydro, Jr.

|

1-in x 12tpi die fits ram, external punch fits FPH-1-H floating punch holder in press head

|

|

-M

|

Discontinued Corbin Presses:

Mity Mite

Silver Press

|

These older-style dies have been replaced by the -S type. They are made on special order for older presses.

|

|

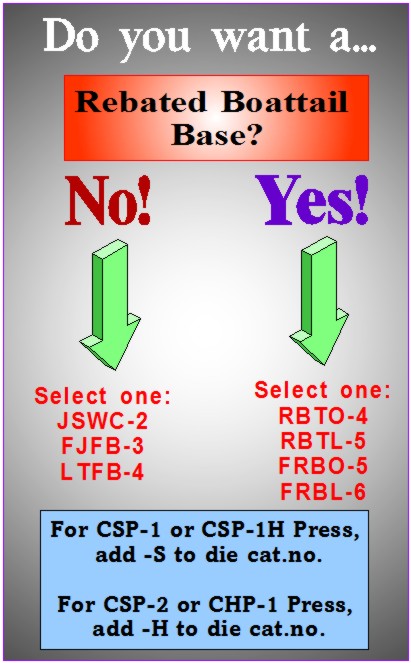

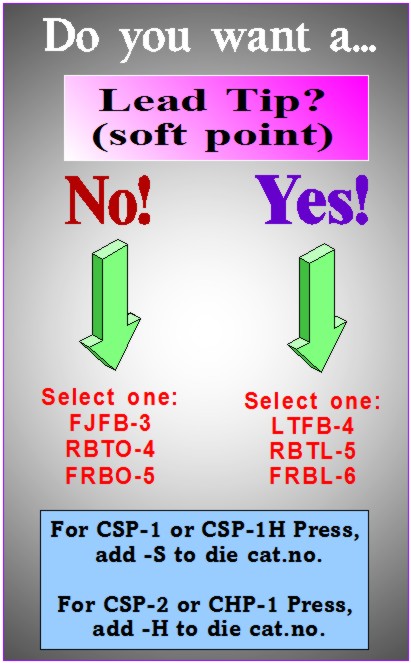

DIE SETS

Although you can order each individual die to make up sequences of operations, or "sets", it is more convenient to order commonly used sets by a single catalog number. The price is the same, and you can add additional dies to expand the capability of any set, at any time.

For instance, you can order a CSW-1-S core swage to make exact core weights, a CS-1-S core seater to put the cores into the jackets and expand the jacket to size, and a PF-1-S point former to shape the ogive on the seated core and jacket and thus finish the bullet. OR you could just order the three dies, as a set, called the Full Jacket Flat Base set or FJFB-3-S. This is the "3-die set" which is the basic starting point for almost any bullet other than wadcutter or semi-wadcutter (shouldered) styles.

Later, you might want to add rebated boattail capability, so you could order the RBT-2-S Rebated Boattail 2-die add-on set. Now you would have the same thing as if you had ordered the FRBO-5-S 5-die set. Count'em. You have five dies total, and can use them for either flat base (3 dies, using core seater) or rebated boattail (4-dies, using the RBT-2 sequence and not using the CS-1-S core seater at all).

For clarity, the catalog numbers are all for type -S dies. But you can also get them all in the type -H or type -M (obsolete, but made for older presses). Not all are available for the -R (reloading) press due to limitations of reloading presses for swaging.

|

LSWC-1-S

|

Lead Semi-Wadcutter, 1-die "set"

|

Adjusts core weight and forms finished lead, gas checked, or BG-type bullet in wadcutter or semi-wadcutter styles, all in one stroke. Cannot put a curved ogive in a jacket or use a jacket that covers the bleed holes in the die. Nose and base are formed against punch ends. Round, Keith, conical and other nose shapes are formed by using a cavity in the punch end. Great for lead pellets, lead pistol bullets, shotgun slugs, hollow base muzzle loader bullets, and similar styles.

|

|

JSWC-2-S

|

Jacketed Semi-Wadcutter, 2-die set

|

Consists of CSW-1 and CS-1 dies. The CS-1 is normally about .0002 inches smaller than the final bullet diameter, so the core and jacket combination will fit into the PF-1 die for final shaping of the ogive. When used alone, you can specify exact diameter (in which case, the set would require a slightly oversized point form die if you ever added one) or just allow the bullet to be slightly smaller. Normally that amount does not hurt accuracy but it permits you to add a standard size point form die later. (The point form die expands the bullet the final .0002 inches or so as it shapes the ogive curve).

This set is ideal for 3/4-jacketed (so-called) pistol bullets, to cover the entire bore/rifling contact area with the jacket, and leave only the actual nose itself as exposed lead. The jacket cannot curve around the nose, because first it would impact the edge of the nose-forming punch.

|

|

FJFB-3-S

|

Full Jacket Flat Base, 3-die set

|

This set can do what the JSWC-2 does, since it has the same first two dies (provided you order it with an optional SWC nose punch). It can also process a jacketed core further in the PF-1 point forming die, to give the bullet a smoothly curved, jacketed ogive. The tip can be open, or lead can come to the end of the jacket. In blunt ogive shapes (round noses or truncated conical pistol noses) a lead tip can also be made. (In sharper pointed rifle bullets, the lead tip can still be made but it will be deformed by the ejection pin -- a LT-1 lead tip die follows up with a reshaping action for good pointed lead tips). You can also make open base, full metal jacket military style bullets by reversing the jacket in the point form die. An optional "FMJ Base Turning" punch helps make a nice crisp base roll-over.

You would order by caliber and by shape of ogive. For instance, an FJFB-3-S .452 3/4-E means .452 caliber (45 ACP) with a 3/4-caliber length elliptical nose shape (standard military ball).

|

|

LTFB-4-S

|

Lead Tip Flat Base, 4-die set

|

This is simply the FJFB-3 with a LT-1 lead tip finishing die added. For factory-finished looking lead tips, especially on the more pointed "spitzer" rifle bullets, this is a requirement. The LT-1 die does not change the ogive curve, but merely straightens out and sharpens up the shape of the exposed lead tip. The same LT-1 die can be used with different internal punches, for use with other shapes of PF-1 point formers. One LT-1 die in 308, for instance, will handle round nose, 4-S, 6-S, ULD, and other nose shapes created in different point forming dies, just by changing the PUNCH-S 308 INTERNAL LT punch shape.

|

|

RBTO-4-S

|

Rebated Boattail Open Tip, 4-die set

|

If we removed the CS-1 core seater (flat base) from the FJFB-3-S die set, and replaced it with the RBT-2-S two-die rebated boattail forming set, we'd have a 4-die package that made open tip RBT bullets instead of flat base bullets. Swage the core, insert the core into the jacket, insert the combo into the BT-1 die and seat the core. This forms an angled conventional BT base. Now move the seated core/jacket into the slightly larger bore of the BT-2 die, which creates the gas sealing step shoulder when you again pressurize the core. Using an external punch that has the RBT cavity in it, you push the seated core/jacket into the point forming die, and you have a finished RBT-OT bullet!

|

|

RBTL-5-S

|

Rebated Boattail Lead Tip, 5-die set

|

This also makes open tips, because any lead tip set can do that. What we have done is simply added the LT-1 lead tip shaping die to the previous set (RBT0-4-S). That lets us do everything we did before, plus we can now seat a longer core or use a shorter jacket with the same core, and have exposed lead tips. As pointed out previously, a lead tip coming out of the point forming die is subject to some deformation by the ejection pin (unless the bullet is a blunt round nose or flat tip). The LT-1 die cleans it up. It is never used alone or to reshape the ogive curve itself.

|

|

FRBO-5-S

|

Rebated Boattail and Flat Base, 5-die set

|

This set simply has the RBTO-4-S set plus a CS-1-S core seater. It can be used as a 3-die set (flat base) or a 4-die set (RBT base). You don't use all five dies on the same bullet. There is no purpose, and it would just cause trouble getting the parts into the next die. Each die is very exactly sized to be slightly larger than the last step, so that the parts will go in, expand under pressure, relax and spring back very slightly to release the grip on the die wall, and eject easily. As the bullet progresses from one step to the next, it grows very slightly larger, until it reaches precisely the correct desired diameter in the last stage.

|

|

FRBL-6-S

|

Flat, Rebated, Lead tip, 6-die set

|

We call this the "all-style" set. It makes open tip or lead tip, flat base or rebated boattail base. (It does not make every shape or caliber, of course, in one set). You would never use all six dies on the same bullet. But you might use five: swage the core, seat the core in the BT-1 and then the BT-2 die, form the ogive in the PF-1 die, and finish the lead tip in the LT-1 die. You could also use just 3 of them, the FJFB-3-S which consists of core swage, core seat and point form. You can see we just added one of each basic kind of die to make this set. It covers all the bases.

|

|

|

Swaging Diagram (1)

Swaging Diagram (2)

Ultra-Low Drag (ULD)

Base Guards(TM)

HP, OT bullets

Elliptical Ogives

Copper tubing jackets

How to Swage

Swaging Books

Software

|

You can order a swaging package by sending samples, drawing, or photo of the bullet you wish to make, and this information:

- Actual bullet diameter (if different from caliber)

- Whether bullet is paper patched, jacketed, lead, or other design.

- Weight range desired

- Type of jacket (if any)

- Corbin standard (we supply)

- Your supply (send 10-12 samples)

- Tubing jackets (CTJM-1)

- Corbin tubing (we supply)

- Your tubing (send 2-3 feet)

- Drawn strip (JMK)

- Corbin supplies 5, 50-lb

- You supply (send 3-4 feet)

- Re-drawn Jackets (JRD)

- Corbin jackets and draw die

- You supply (send 10-12 samples)

- Turned solids

- Corbin quote for production

- You supply (send 10-12 samples)

- Type of core

- Lead wire (LW-10, and PCS-1 or PCS-2 core cutter)

- Cast cores (CM-4a core mould)

- Powder metals (specify)

- Corbin Atomized Copper

- You supply (send samples to make 10 bullets)

- Monolythic solid

- Soft lead (LW-10 or cast core)

- Alloy lead (send 10-12 samples)

- Copper (send 1-2 foot sample)

- Brass (send 1-2 foot sample)

- Other (specify, send sample)

- Nose style

- SWC or WC shouldered (LSWC-1)

- Standard shape outline

- Custom shape outline

- Integrated conical HP

- Splined, other special design

- Ogive curved (PF-1)

- Standard pistol shape (3/4-E, TC)

- Standard rifle shape (1-E, 6-S)

- ULD-TIP (special with metal insert)

- Custom shape (specify)

- Tip design

- Lead tip (LT) (specify shape)

- Open tip (OT) (core below jacket)

- Hollow point (HP) (punch, in CS step)

- ULD-TIP w/metal insert

- Full Metal Jacket (FMJ)

- Other (specify)

- Base design

- Flat base (FB)

- Dish base (DB) <= .1 cal.

- Cup base (CB) > .1 < .5 cal

- Hollow base (HB) >= .5 cal

- Heel Base (specify diam/len)

- Rebated Boattail (RBT)

- Custom (specify)

- Shank design

- Conventional straight

- Dual diameter

- Serrated full length

- Serrated forward only

- Other (specify)

|

|

|

Now you should know what a die set does, how many dies are in it, and what press it fits, just from the catalog number! Here are some examples:

- FRBL-6-M .308 8-S means Flat and Rebated Boattail, Lead Tip (and open tip) six die set for the Silver Press or the S-press, in .308 caliber, with an 8-S spitzer ogive for the point form die and matching lead tip punch.

- FJFB-3-H .458 1-E means Full Jacket Flat Base (open tip or, by reversing the jacket, military FMJ open base) three-die set in .458 caliber with a 1-E ogive (one caliber elliptical round nose shape).

- LSWC-1-M .400 TC CB means Lead Semi-Wadcutter single die set for the discontinued Silver Press, in .40 caliber, with a truncated conical nose and a cup base. You can change the nose and base punch for $20 each to make different noses and bases in this kind of die set.

- PRO-1-R .448 PP 1-E CB means Pro-Swage single die set for reloading press, in .448 diameter for paper patching (probably for .45-70 caliber) with a 1 caliber elliptical nose and a cup base.

- LTFB-4-R .224 6-S means a lead tip and open tip flat base four die set for the reloading press in .22 centerfire caliber with a 6-caliber spitzer radius nose curve.

|

Click a picture for information about standard and special punch types for type -R, -S, and -H die sets. The punches are the "rods" that move inside the dies. They seal the pressure within the die. The internal punch stays inside the die and moves toward the die mouth to eject the component or bullet. The external punch separates from the die on each stroke of the press, to allow insertion of another component and to make room for ejection. Please do not call a die a punch, or vice versa, as it will be very confusing and your orders will often be wrong. Ordering a "die-punch" also makes no sense to us, because either you want a die (the cylinder that holds the pressure) or a punch (the piston or rod that fits into the die), or perhaps you want the complete "die set" which is the die with its associated punches. If you want a punch, you will want either an external punch, or an internal punchl. Usually we can tell by the context, but it helps if you learn the difference and order what you really want.

Click a picture for information about standard and special punch types for type -R, -S, and -H die sets. The punches are the "rods" that move inside the dies. They seal the pressure within the die. The internal punch stays inside the die and moves toward the die mouth to eject the component or bullet. The external punch separates from the die on each stroke of the press, to allow insertion of another component and to make room for ejection. Please do not call a die a punch, or vice versa, as it will be very confusing and your orders will often be wrong. Ordering a "die-punch" also makes no sense to us, because either you want a die (the cylinder that holds the pressure) or a punch (the piston or rod that fits into the die), or perhaps you want the complete "die set" which is the die with its associated punches. If you want a punch, you will want either an external punch, or an internal punchl. Usually we can tell by the context, but it helps if you learn the difference and order what you really want.