|

High BC and Undersize Bullets

Making the ogive (nose section) of a bullet longer, with the same size tip, means that there is more volume of material in the ogive. In order to have the same bullet weight that you would with a shorter ogive, the shank (full diameter, cylinderical portion) of the bullet must become shorter in proportion.

Making the ogive (nose section) of a bullet longer, with the same size tip, means that there is more volume of material in the ogive. In order to have the same bullet weight that you would with a shorter ogive, the shank (full diameter, cylinderical portion) of the bullet must become shorter in proportion.

At left are bullets from 2-S to 12-S ogive curve, with the shortest shank that normally provides good balance and accuracy for each bullet. Note that the longer the ogive, the more weight will be added to the bullet, so that the minimum practical weight will go up as the ogive becomes longer. Attempts to make the same weight in the 12-S high BC ogive bullet as in the 2-S low BC bullet will be doomed to failure.

The external punch, which pushes the bullet material into the point forming die, is made to fit the full shank diameter closely. If you attempt to make too light a bullet, you will push the punch into the smaller diameter ogive section of the die, ruining the punch by rolling over the edge and possibly sticking the punch. A punch that makes a boattail or rebated boattail shape has a thin edge around the BT cavity. Pushing this punch too far into the die will result in either cracking the edge of the punch, or rolling over the edge, which will cause leakage of lead around the punch, and a rough edge on the bullet. It may also cause the bullet to tend to stick in the punch. To prevent this, we normally make the punch with a shoulder that contacts the die mouth just as the punch reaches the ogive. This prevents the punch from going too far into the die.

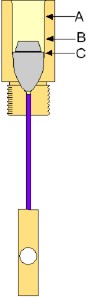

In the illustration at right, a point forming die is depicted with a rebated boattail lead bullet. The arrow "A" indicates the heaviest bullet that should be made in the die (allowing about a caliber length for the external punch to enter the die). The arrow "B" indicates the lightest stable bullet that should normally be attempted, which allows almost a caliber of straight shank at full diameter on the bullet. The arrow "C" indicates the start of the ogive curve in the die, which is the shortest bullet that can be made, although it probably will be undersized by .0005 to as much as .002 inches. The reason is that the bullet is being pushed entirely into the ogive. The external punch probably will be damaged unless it has a shoulder that prevents the punch from reaching into the ogive and becoming reduced or rolled over at the edge.

Especially with lead bullets (such as airgun pellets and blackpowder rifle bullets), there is a tendancy for bullet makers to design higher BC projectiles by making the ogive longer and then attempting to make light bullets that would be in the same weight range as a shorter ogive design. This means the amount of material used is too small an amount to both fill the longer ogive area, and also to allow some material at full bullet diameter. The result is that the bullets have no shank. The punch pushes the bullet material right up to the ogive, where it is normally stopped by the safety shoulder on the punch. But the bullet appears to be undersized by a small amount, because the punch reaches the start of the ogive. At that point in the die, the nose has started to curve inward, reducing the diameter.

If you find that a given bullet, especially a lead one, is coming out "too small" in diameter, and yet the die is marked with the proper diameter, make sure that the length of bullet is enough to assure the entire ogive is filled with at least some amount being formed in the full diameter cylindrical section of the die, where the bullet shank should be created. It is a common mistake to extend the length of the nose, to gain BC, and then try to use a weight that is no longer suitable for such a bullet. To see if this is the case, try making a bullet at least twice as heavy as the one that measures "undersized", and then see if the heavier, longer bullet now measures correct diameter. If so, you are simply making too light a bullet in that die.

Now, what can be done to make a lighter bullet in a die that requires a longer ogive? Here are some methods that may work, depending on the amount of weight reduction required:

- Use a hollow point punch when forming the core. This lets you remove some weight from same length of core. The center of gravity is shifted to the rear of the bullet, which if carried to extremes will require too fast a twist to keep the bullet stabilized. But in moderation, a hollow cavity can lower the weight for a longer ogive bullet. The diameter of the hollow point punch and its length will control the amount of mass that is displaced by the cavity. Two limitations are the remaining strength of the walls left in the bullet (too thin, and the bullet may become too fragile for handling or forming the ogive without crushing the bullet), and the minimum bullet length compared to the length of the cavity (too long a punch may limit the minimum bullet length).

- Use a hollow base punch for shotgun slugs, Minie-type bullets, and airgun pellets. The same limitations apply as with the hollow point. In addition, the thickness of the walls around the hollow base cavity (known as the "skirt thickness") must allow enough strength so that the bullet will not be expanded at the muzzle by gas or air pressure. Muzzle pressure can be high enough to severely deform the skirt of a hollow base bullet, if the walls are too thin.

- Use a low density filler such as plastic balls or cornstarch in the cavity, which will strengthen thin walls by providing internal support. Powdered material can be compressed in a core seating die so it stays in place during point forming, when the bullet is inverted.

- Use a lower density bullet material. Pure lead weighs more than alloyed lead, so a harder lead alloy (within reason) can lighten the bullet and allow the same length. This is a reasonable solution if the hardness does not exceed die limits.

- Truncate the ogive. The long ogive can end before it reaches the centerline, as with a flat tip or a hollow point left open. This effectively removes weight, and shortens the ogive without changing the ogive curve. The effect on BC is less than if the ogive curve itself is changed, for relatively small amounts of tip opening or flat tips that are a small percentage of caliber.

All these methods have narrow limits within which they are practical. The bottom line is that longer noses require more weight if you are to have any full-diameter shank left on the bullet, and these methods are all compromises in some way with the length versus the weight, which affects the BC.

Since the ballistic coefficient of the bullet is sometimes given far too much attention at the expense of nearly everything else, it is a good idea to review the goal of a new design. If the reason for wanting a higher BC is just the bragging rights, then there are many ways to accomplish this by ignoring accuracy, required spin rate, and other performance factors. A high BC does not automatically translate to high accuracy. It is not an over-all figure of merit, but only a ratio of how quickly one bullet loses speed compared to some standard bullet.

The BC figure says nothing about accuracy. It is increased directly with the bullet weight, so that if all else is equal, a lighter bullet will have lower BC than a heavier one. It is also inversely proportional to caliber, so that if all else is equal, a smaller diameter bullet has a higher BC than a larger one. The ease with which a supersonic bullet moves through the air is related to the angle of its nose curve or ogive, so that the more pointy the bullet, the higher the BC (to a rapidly approached limit...the curvature is a log function, not linear, so that going from a 1-S to a 2-S curve is a much greater change than going from an 8-S to a 10-s curve).

Subsonic (below about 1090 fps depending on air density) bullets have their BC more affected by the shape of the base than the nose. A very blunt bullet can have its BC improved by nearly 40% by changing from a flat base to a rebated boattail shape, whereas a supersonic bullet will only improve by 10-15% by changing the base, because the shock wave generated at the nose is so much greater an effect than base drag. Without the shock wave, most of the drag is at the base. Therefore, subsonic airgun, shotgun, and blackpowder bullets do not really need a longer ogive to get higher BC in comparison to using a boattail shaped base. The problem is that a boattail base is incompatible with a hollow base for sealing the bore. Therefore, a special under-cut form of rebated boattail may be used to create a seal at the boattail shoulder.

In order to increase the BC, you can increase the weight, decrease the diameter, sharpen the ogive, or replace a flat base with a boattailed shape. To increase the weight in the same length of bullet, you can use a higher density material. For instance, pure lead has a higher density than alloyed lead. Or, tungsten powder has somewhat higher density than solid lead (it has 1.7 times the density of the same granulation and compression of powdered lead, but any compressed powder will tend to be less dense than its solid form).

Problems that can occur with going for higher BC, for its sake alone, include making bullets that are too heavy for the caliber, or too long for a practical rifling twist rate. The accuracy of a high BC bullet can be lower than a normal BC bullet because the extra length of the nose may also require a matching longer shank, so that the overall bullet length is unstable with conventional rifling twists. Using a faster twist barrel adds to instability caused by variations in bullet concentricity, since the bullet spins quicker (higher RPM). Just as an automobile tire may be stable and smooth running at 50 mph, but begin to vibrate and shake the car at 100 mph, the faster-spinning bullet will tend to wobble more than if it were spinning slower. This can lose more in accuracy than the BC gains in flatness of shooting, if these two different factors can be compared.

Accuracy and flat shooting are not the same thing. It is easier for the shooter to hit the target if the bullet doesn't drop as much, but this is a matter of skill and not mechanical precision. A bullet can be lobbed at a high, mortar-like angle into one hole groups (or, as in the early days of .45-70 class shooting at 1000 yards, at least into 20 inch bullseyes). If the gun is mounted on a mechanical stand, it may be capable of excellent accuracy even with a very poor BC bullet.

In fact, perhaps it will be more accurate with a low BC bullet, since the low BC bullet probably is short and does not require much spin to be stable, minimizing the effects of any eccentric mass in the bullet. If the reason for seeking extreme BC is to make the bullet more flat shooting (that is, to decrease the amount of drop over a given range), and the reason for wanting less drop is to gain accuracy, then there is a problem with the idea. Less drop is not automatically the same as more accuracy.

If the reason for seeking higher BC is to reduce energy loss, to deliver higher energy to the target, then the idea makes perfect sense. A heavier, longer bullet with a sharper ogive will tend to do just that. But there is a trade-off. If the bullet needs to be heavier, it probably can't be driven as fast. If it is launched at lower velocity, it will have less energy. It is quite possible that a lighter bullet, with lower BC, fired at higher velocity, may reach a given range with more energy than a higher BC, heavier bullet fired at much lower velocity. There is no easy answer: you have to work out the figures and see for yourself.

And now we are at the real bottom line: there is no easy answer. Seeking some arbitrary high number in any particlar direction is an attempt at getting an easy answer without really knowing the question. But finding the right answer can be both educational and enjoyable...and it results in real improvements, instead of just arbitrary changes. Consider all the factors, and find the balance that achieves the goal. That means knowing the goal before you start!

|