|

The Corbin Bullet Knurling Tool (HCT-2) creates diamond-pattern knurling on lead bullets.

The diamond knurls form tiny "waffle" patterns on the bullet surface, which hold lubricant like a waffle holds syrup: up to 200 percent more lubricant in contact with the bore than conventional grooves.

The Corbin Bullet Knurling Tool (HCT-2) creates diamond-pattern knurling on lead bullets.

The diamond knurls form tiny "waffle" patterns on the bullet surface, which hold lubricant like a waffle holds syrup: up to 200 percent more lubricant in contact with the bore than conventional grooves.

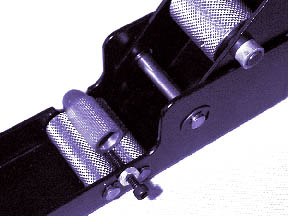

The lead bullet is placed on a knurled roller V-way, and a steel

embossing wheel is brought into contact with the other side of the bullet by

lowering a large, expanded-neoprene covered grip and pressing down upon the bullet

while you turn a small crank one or two spins. The massive grip and long leverage makes the job easy even with the largest lead slugs.

The tool is designed for any caliber between

.224 and .720 diameter and adjusts automatically for diameter of bullet in two ranges, from .224 to .458, and from .375 to .720. To select the range, remove one e-clip and put the pivot pin in the alternative set of holes linking the top and bottom of the device together. This means the same tool can be used to cover all calibers from 22 to 12 gauge shotgun!

The hard chromed precision ground steel roller V-way supports the bullet horizontally, so you can press straight down for maximum leverage and ease of use.

Since both ends of the rollers are supported in the steel frame, there is no

"creep" caused by spreading of one end of the supports, a common complaint with certain earlier brands of cannelure tools.

Each bullet looks just like the last.

The HCT-2 is not recommended for jacketed bullets. Corbin has

the HCT-1 Cannelure Tool for jacketed bullets and the

HCT-3 Grooving Tool for larger caliber lead bullets (applies two wide lube grooves at a time). Production speeds can be achieved with the Corbin PCM-2 Power Cannelure

Machine (100 or more bullets per minute).

For these and other accessories, see the Corbin price list. VISA/MC orders welcome.

|

|

Questions?

Can I use the HCT-2 with hard lead bullets?

The HCT-2 works best with soft lead or lead not over Bhn 8-10 (medium) hardness. The entire shank of the bullet is knurled, which can require far too much effort with hard lead. It is easy with soft lead.

What calibers work with the HCT-2?

The HCT-2 cannelure tool works automatically with .224 to .720 caliber lead bullets.

Is the HCT-2 sold through dealers?

As with all Corbin tools, the HCT-2 is available directly from Corbin. You can order on-line using your credit card.

How is lubricant applied?

By rolling, dipping, spraying or dusting with moly or graphite. Or by spraying with a dry-film moly lube.

Does the diameter of the bullet change?

This is a tricky question because the diamond points are higher than the previous surface, so in one sense the diameter is larger after knurling. But there are an equal number of depressions formed, which are lower than the original surface. The average diameter is the same. The raised surface is more easily pressed down when seating the bullet or when firing it, since all you are doing is pushing down the tiny points of raised diamonds. But when this happens, the lube is squeezed up to the surface, which is exactly what you want to happen in the bore. If it is critical to keep the absolute maximum diameter the same, then you should (1) make the bullets somewhat smaller and knurl them to increase to desired diameter (within a few thousandths) or (2) push the bullet through a sizer die after it has been dipped in lube, so that the lube is gripped tightly and sealed into the depressions. (If you size before lubing, the diamond points are pushed back down into the empty depressions and less room is left to hold lube).

Can I use knurling on cast bullets?

Can I use knurling on cast bullets?

Yes. Many people add knurling to factory cast bullets for greater lube retention.

Are the bullets accurate after being knurled?

Yes, because of the three-point, equal pressure design of this tool, any distortion is quickly leveled out and occurs only temporarily in a concentric, three-lobe pattern. If you change a round object into a three equi-distant lobed shape, it remains concentric about the axis. But the amount of variance is so slight that rotating the bullet round twice automatically evens out the differences.The depth of knurling is sufficient to hold the lubricant, but not so deep that it causes permanent distortion.

How fast does it work?

Place the bullet on the roller V-way, set the depth and position screws to your liking, and give the crank two complete turns. Once set, you can drop bullets onto the rollers and apply knurling at a rate of about 5-6 per minute. If you need more speed, get the PCM-2 power cannelure machine: it can process over 100 bullets per minute!

How repeatable is the knurling?

They are precisely the same from one to another, as long as you use the depth and position adjustments as intended. You can also quickly make knurling without using the adjustments, and still get them rather closely matched just by feel alone.

How long does the tool last?

With soft lead bullets, there is very little wear.

It is necessary to keep the bearings oiled and to drop a little oil on the roller shafts from time to time. We do not recommend or warranty the tool when used in commercial high volume applications: for that, we make the PCM-2 Power Cannelure Machine. Typical use of the HCT-2 would be to apply knurling to a box of 50 or 100 bullets once or twice a month. In that application, the tool has virtually unlimited life if the bearings are kept oiled.

Can the tool be converted to a cannelure tool?

Yes, in theory. You could purchase the parts and disassemble the tool, replace the necessary parts and have a cannelure or grooving tool. But because the parts handling and stocking is fairly expensive compared to stocking just completed tools, it is not particularly economical to do this. The snap-ring retainers used to hold the rollers in the tool would need to be replaced unless you purchase the appropriate disassembly and assembly plier tools to gently remove and replace them. By the time you do all this, it is actually just as economical to purchase one of each type of tool. And it is a lot more convenient to have them ready when you need them.

Can I get literature on the tool?

Yes, in fact there is more information already here on this page than on the printed literature. If there is anything you want to know that has not been covered, it probably isn't in the printed literature either: send an e-mail with your question and we'll answer it as soon as possible.

|