|

The tools you need depend on the bullet you want to make:

- A lead bullet with a step or shoulder between nose and shank (like a Keith or SWC or Wadcutter) can be made in a single die, called the "LSWC-1". Hollow base shotgun slugs, and airgun pellets, are also made with this kind of die.

- Calibers from .10 to .458 inch can use the LSWC-1-S die and the CSP-1 S-Press.

- Calibers from .459 to 1.00 inch can use the LSWC-1-H die and either the CSP-2 Mega Mite or the CHP-1 Hydro Press.

- A reloading press can also be used, with the PRO-1-R ProSwage die.

- A lead bullet without a step or shoulder between nose and shank (a smooth ogive bullet) can be made in a two dies, called the core swage (CSW-1) and the point form (PF-1).

- Calibers from .10 to .458 inch can use type-S dies and the CSP-1 S-Press.

- Calibers from .459 to 1.00 inch can use type-H dies and either the CSP-2 Mega Mite or the CHP-1 Hydro Press.

- A reloading press can also be used with a custom CSW-1-R and custom PF-1-R die. Except in .224, .243, and certain pistol calibers (.32 to .38), the -R dies are only available on custom order.

- A jacketed bullet with a step or shoulder between nose and shank can be made in a two dies, called the core swage (CSW-1) and the core seater (CS-1). This combination is called the "JSWC-2-S" or "JSWC-2-H". You can order the two individual dies, or the single catalog number for them both.

- Calibers from .10 to .458 inch can use type-S dies and the CSP-1 S-Press.

- Calibers from .459 to 1.00 inch can use type-H dies and either the CSP-2 Mega Mite or the CHP-1 Hydro Press.

- A reloading press can also be used with a custom CSW-1-R and custom CS-1-R die. Except in .224, .243, and certain pistol calibers (.32 to .38), the -R dies are only available on custom order.

- A jacketed bullet without a step or shoulder between nose and shank, and a flat or cupped base can be made in a three dies: the core swage (CSW-1), the core seater (CS-1), and the point former (PF-1). This combination is called the "FJFB-3-S" or "FJFB-3-H". You can order the three individual dies, or the single catalog number for all three in a matched set. The core swage (CSW-1) is optional, but is usually desired as part of the set, for more accurate weight control.

- Calibers from .10 to .458 inch can use type-S dies and the CSP-1 S-Press.

- Calibers from .459 to 1.00 inch can use type-H dies and either the CSP-2 Mega Mite, or the CHP-1 Hydro Press.

- A reloading press can also be used for .224 or .243 bullets, with the BSD-224R or BSD-243R die sets, which have the CS-1-R and PF-1-R (the CSW-1-R can be ordered as an option).

- A jacketed bullet without a step or shoulder between nose and shank, and a rebated boattail base can be made in a four dies: the core swage (CSW-1), the boattail preformer (BT-1), the rebated boattail former (BT-2) and the point former (PF-1). This combination is called the "RBTO-4-S" or "RBTO-4-H".

You can order the four individual dies, or the single catalog number for all four in a matched set. You can also add a kit consisting of the BT-1, BT-2, and a RBT punch for an existing point form die, as an add-on RBT package for any flat base 3-die set. This is the RBT-2-S or RBT-2-H set.

You can order the four individual dies, or the single catalog number for all four in a matched set. You can also add a kit consisting of the BT-1, BT-2, and a RBT punch for an existing point form die, as an add-on RBT package for any flat base 3-die set. This is the RBT-2-S or RBT-2-H set.

- Calibers from .10 to .458 inch can use type-S dies and the CSP-1 S-Press.

- Calibers from .459 to 1.00 inch can use type-H dies and either the CSP-2 Mega Mite or the CHP-1 Hydro Press.

- A reloading press is not suitable for RBT type bullet swaging.

- A jacketed bullet with a factory-finished lead tip can be formed by adding a lead tip (LT-1) die to either the 3-die flat base or the 4-die rebated boattail sets above. You can order three ways:

- Order a complete set of dies using one of these catalog numbers:

- LTFB-4-S or -H, for flat base, open or lead tip bullets.

- RBTL-5-S or -H, for rebated boattail, open or lead tip bullets.

- FRBL-6-S or -H, for flat OR rbt, open OR lead tip bullets.

- Order the LT-1-S or -H for an existing FJFB-3, RBTO-4, or FRBO-5 die set.

- Order the individual dies, including the LT-1-S or -H.

Making lead tip bullets in a reloading press:

- Reloading press die sets that include a PF-1-R can be upgraded to lead tip by adding a LT-1-R die, in .224 or .243.

- A set of -R type dies can be ordered as the LTFB-4-R (core swage, core seat, point former, and lead tip finishing dies).

- Individual -R dies can be ordered, including the LT-1-R.

- A flat base can be added to any rebated boattail set by adding the core seater (CS-1) to an existing RBTO-4 or RBTL-5 die set. This can be done in two ways:

- Order a complete set of dies using one of these catalog numbers:

- FRBO-5-S or -H, for flat or rebated boattail, open tip bullets.

- FRBL-6-S or -H, for flat or RBT, open or lead tip bullets.

- Order the CS-1-S or -H for an existing RBTO-4 or RBTL-5 die set.

- Order the individual dies, including the CS-1-S or -H.

For a good background in swaging, get Handbook of Bullet Swaging, No.9 on CD-ROM. This gives you quick lookup and instant access to information on nearly every aspect of swaging at very low cost. Corbin bullet design software can help you design bullets without a math or engineering background: just fill in the blanks, click "calculate", and get a wealth of information about any bullet your imagination can suggest!

|

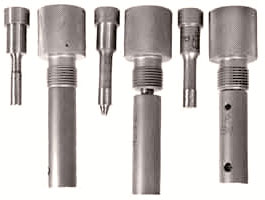

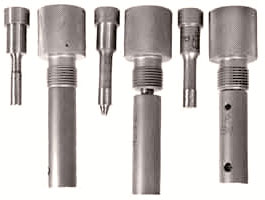

Dies are classified by the kind of press they fit, and the kind of operation they perform.

Dies whose catalog number ends with -R fit a standard 7/8-14 thread reloading press with slotted ram, similar to the RCBS Rockchucker. The die goes into the press head, like a reloading press die. The external punch fits into the press ram, like a shell holder. Ejection is by means of a plunger or knock-out rod in the top of the die.

Type -S Dies

Dies whose catalog number ends with -S fit the Corbin S-Press. The dies have 5/8-24 threads and fit into the press ram, so you can drop parts into the die mouth. The press head is 7/8-14 threaded. The press comes with a floating punch holder, which is used to hold and adjust the position of the external punch. This punch pushes components into the die and applies pressure to them. Ejection is automatic on the down stroke.

The -S dies make bullet lengths up to 1.3 inches (maximum length for any component) and diameters up to .458 inches.

Type -H Dies

Dies whose catalog number ends with -H fit the Corbin Hydro-Press and Mega-Mite Press. These dies have 1-inch x 12 threads and a 1.5-inch main body. The dies fit the press ram. The external punch fits a floating punch holder (which comes with each press). The punch holder goes in the top or head of the press, and adjusts the position of the punch. Ejection is automatic on the down stroke. Bullet length can be longer than 2 inches and the diameter can be as much as 1 inch.

Dies whose catalog number ends with -H fit the Corbin Hydro-Press and Mega-Mite Press. These dies have 1-inch x 12 threads and a 1.5-inch main body. The dies fit the press ram. The external punch fits a floating punch holder (which comes with each press). The punch holder goes in the top or head of the press, and adjusts the position of the punch. Ejection is automatic on the down stroke. Bullet length can be longer than 2 inches and the diameter can be as much as 1 inch.

Type -M Dies

Early Corbin dies for the discontinued Mity Mite and Silver Press used a 3/4-inch diameter body with 5/8-24 threaded shank. These dies are made today on special order to fit the early model presses. They have been replaced by the type -S dies.

|

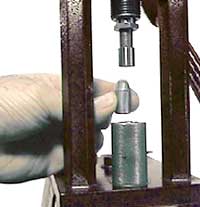

Making A Bullet

The first step in swaging any bullet is adjusting the weight of the core. The core can be lead, or some other material. It can also be the entire bullet (for lead bullets), or just the filling for the jacket (which is the cup or shell around the core). This is an optional but highly recommended first step. You can skip it and make sure your cut or cast cores are as accurate in weight as possible by careful preparation. In that case you do not need the core swage (CSW) die.

The bullet can be made in one step if it has no jacket, and can have a shoulder between the shank and nose. It can be made in two steps, in a core swage and a core seat die, if it has a jacket that does not go past the shoulder. If it has a flat, cup, dish, or hollow base, it can be made in three dies, without a shoulder, with or without a jacket. The jacket can be put in backward to make a full metal jacket, or the lead core can be shorter than the jacket for an open tip. Rebated boattail bases and lead tips are created with other steps. No more than five basic operations are required for swaging any of the bullet styles.

Each step is a single stroke of the press. Each stroke takes from 2 to 5 seconds, depending on the press and the particular operation. Simple lead bullets can be made at 10-12 per minute, jacketed semi-wadcutters at 5-6 per minute, full jackets, soft or hollow point flat bases at 3-4 per minute, and rebated boattail open tips at 2-3 per minute.

The important thing to keep in mind about swaging is that the process works by putting very high pressure on the filling or core, which compresses in length and expands in diameter, pushing the jacket (if used) into exact conformity with the inside of the die. The component you are swaging expands in diameter. When you release the pressure to eject the bullet, the materials shrink back very slightly to release from the die. The jacket stretches, and every void within the sealed die is filled with material. Whatever pressure is applied to the core, or base of the bullet, is also applied to every other part.

|

To get a better understanding of swaging, click the subjects in the following table. (Core swaging is the first operation in making nearly any bullet...)

|

Answers to commonly asked questions about swaging

|

|

Technical support and sales e-mail: sales@corbins.com

FAX: 541-826-8669 -  - PHONE: 541-826-5211 - PHONE: 541-826-5211

|

|

Airgun Slug Swaging with the CSP-1 Press

CORBIN,

PO Box 2659, White City, OR 97503 USA

600 Industrial Circle, White City

|

Dies whose catalog number ends with -H fit the Corbin Hydro-Press and Mega-Mite Press. These dies have 1-inch x 12 threads and a 1.5-inch main body. The dies fit the press ram. The external punch fits a floating punch holder (which comes with each press). The punch holder goes in the top or head of the press, and adjusts the position of the punch. Ejection is automatic on the down stroke. Bullet length can be longer than 2 inches and the diameter can be as much as 1 inch.

Dies whose catalog number ends with -H fit the Corbin Hydro-Press and Mega-Mite Press. These dies have 1-inch x 12 threads and a 1.5-inch main body. The dies fit the press ram. The external punch fits a floating punch holder (which comes with each press). The punch holder goes in the top or head of the press, and adjusts the position of the punch. Ejection is automatic on the down stroke. Bullet length can be longer than 2 inches and the diameter can be as much as 1 inch.