| Home | Presses | Intro | Site Map | P.R. | Chemicals | Answers |

|

| Prices | Specials | How To | Bullets | B.Makers | Books | Classified | |

| Topics | Jackets | Terms | Training | Software | Products | Contact us |

| Home | Presses | Intro | Site Map | P.R. | Chemicals | Answers |

|

| Prices | Specials | How To | Bullets | B.Makers | Books | Classified | |

| Topics | Jackets | Terms | Training | Software | Products | Contact us |

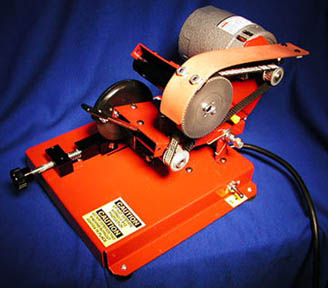

Corbin Manufacturing has just released a second model power saw for cutting tubing to precise length for the manufacture of bullet jackets. The saw operates on 115 volts, with a 10,000 rpm 1/5-HP motor. A geared belt runs a precision ball bearing spindle, which turns a special .032-thick non-ferrous high speed metal cutting blade.

The new SAW-2 model differs from the SAW-1 in having a double ball bearing spindle and additional drive stage, mounted on a sub-deck, which allows the saw to cut infinite lengths by moving the precision stop out of the way. With the adjustable position stop in place, the saw cuts precise short lengths from zero to three inches for jackets. With the stop removed or rotated out of the tubing path, arrow shafting and other long tubing can be cleanly cut to a measured mark on the tube without limit on either end (as for example, cutting standard 20-foot sections into 18-inch sections).

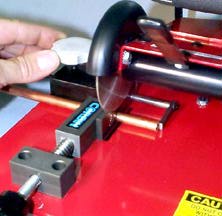

The saw fits into a 9.5 by 9.5 inch space, easily qualifying as a "minature" power tool. But it is far more precise than larger cut-off tools, leaving little or no burr, and maintaining exact alignment of the tubing. A spring-loaded adjustable clamp vise holds copper, brass, or aluminum tubing of 1/8 to 5/8-inch diameter, allowing the stock to be moved along by hand without unfastening the clamp. The tubing stock is pushed up against an adjustable position stop, which sets the length of the jacket to be cut off. The stop can adjust from nearly zero to several inches of tube length, adequate for any small arms caliber including the .50 BMG.

The saw fits into a 9.5 by 9.5 inch space, easily qualifying as a "minature" power tool. But it is far more precise than larger cut-off tools, leaving little or no burr, and maintaining exact alignment of the tubing. A spring-loaded adjustable clamp vise holds copper, brass, or aluminum tubing of 1/8 to 5/8-inch diameter, allowing the stock to be moved along by hand without unfastening the clamp. The tubing stock is pushed up against an adjustable position stop, which sets the length of the jacket to be cut off. The stop can adjust from nearly zero to several inches of tube length, adequate for any small arms caliber including the .50 BMG.

Jacket wall thickness of .020 to .050 inches can be cut cleanly with the tool, by pressing gently on a finger lever, which lowers the saw blade through the material.

Bullet jackets with closed bases can be made from tubing, using Corbin's CTJM- series of tubing jacket makers, with models made for any Corbin press. The advantages of tubing jackets include: easily adjusted lengths, heavier walls than typical factory bullets for superior big game performance, excellent expansion characteristics (especially when used with Corbin Core Bond), relatively low cost tools to make the jackets, and readily available raw materials (over 200 mill outlets supply proper size tubing, and Corbin stocks tubing in 4-foot sections in the .035 inch wall thickness most used by bullet makers).

No license or special permit is required to manufacture bullet jackets from tubing, nor to make bullets from the material. (Selling the bullets to the public requires a Class 6 FFL.) The alternative methods of cutting tubing have these drawbacks:

No license or special permit is required to manufacture bullet jackets from tubing, nor to make bullets from the material. (Selling the bullets to the public requires a Class 6 FFL.) The alternative methods of cutting tubing have these drawbacks:

The Corbin Tubing Saw solves these problems with a quick-to-operate, small size power tool. Order Catalog Number SAW-2.

Order from:

CORBIN

PO Box 2659

600 Industrial Circle

White City, OR 97503 USA

| Home Page | Price List | E-Mail Sales | Site Map | New Products | Auto Q&A | Terminology |

| Retirement | Specials | Real Estate | Software | How to swage | Classified Ads | Feedback |