| Home | Presses | Intro | Site Map | P.R. | Chemicals | Answers |

|

| Prices | Specials | How To | Bullets | B.Makers | Books | Classified | |

| Topics | Jackets | Terms | Training | Software | Products | Contact us |

| Home | Presses | Intro | Site Map | P.R. | Chemicals | Answers |

|

| Prices | Specials | How To | Bullets | B.Makers | Books | Classified | |

| Topics | Jackets | Terms | Training | Software | Products | Contact us |

Core Swaging Core Swaging

|

Core Seating Core Seating

|

Point Forming Point Forming

|

RBT Die Sets RBT Die Sets

|

A conventional boattail bullet has a short, angled slope toward the actual base diameter. Usually, the angle is between 7 and 12 degrees, with 8 degrees being a fairly standard design (no great difference in performance is usually observed with angles in this general range). See RBT SPECS page for more info.

A conventional boattail bullet has a short, angled slope toward the actual base diameter. Usually, the angle is between 7 and 12 degrees, with 8 degrees being a fairly standard design (no great difference in performance is usually observed with angles in this general range). See RBT SPECS page for more info.

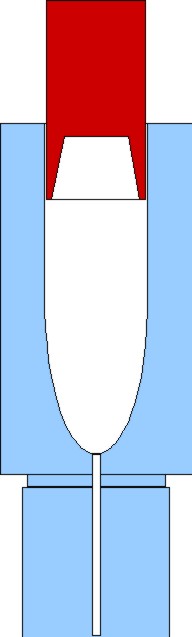

The purpose of the boattail is to reduce air turbulence at the bullet base. In theory, a double-ended bullet would be even better at achieving this, except that it would in most cases make the bullet too long and take up too much powder space in the cartridge. Truncating (cutting off) the base at a somewhat smaller diameter than the bullet caliber reduces base drag enough to make a noticable difference in performance at longer ranges.  A RBT or Rebated Boattail base is an advanced form of the conventional boattail base, which adds a 90-degree step or shoulder between the angled base and the shank of the bullet, to act as a "spoiler" and break up muzzle gas flow, provide a better seal in the bore, and cause a more rapid and concentric transition from the muzzle to free flight than a boattail angle emerging from the barrel. See Rebated Boattail page for details and illustrations.

A RBT or Rebated Boattail base is an advanced form of the conventional boattail base, which adds a 90-degree step or shoulder between the angled base and the shank of the bullet, to act as a "spoiler" and break up muzzle gas flow, provide a better seal in the bore, and cause a more rapid and concentric transition from the muzzle to free flight than a boattail angle emerging from the barrel. See Rebated Boattail page for details and illustrations.

A conventional boattail bullet tends to focus the 10,000 fps muzzle gas into a ball in front of the emerging bullet, just like a water hose nozzle focuses the water into a stream. Then the conventional boattail bullet must pass through the turbulent ball of gas, and is buffeted about more than the rebated boattail bullet, which passes through clear space as a ring of gas expands outward from the rebate step on the back of the bullet. Click for Illustration It is simple to make a RBT base bullet with good accuracy and repeatability, using a step punch to create and maintain the base shape. But it is difficult to create a good BT base using a punch. In essence, one needs to put a "nose" on both ends of the bullet in order NOT to have a step on the base. Most people immediately suggest using a punch with a boattail cavity to form the boattail base. The problem with this is the thin edge of the punch required to avoid a step.  Most of the high strength steels used for swage punches can handle being pressurized to 20,000 and up to 50,000 psi during swaging, then being pulled back while pressure is still applied, if they have at least .015 inches of thickness at the thinnest edge that is under pressure. A punch brought right to the die wall, as in a conventional boattail shape, would have zero edge thickness. It might make one bullet before the moving punch was ripped apart at the edge, leaving a ragged .015 inch margin and leaving the remains of the thin edge stuck in the bullet or pushed out as bits and pieces.

Most of the high strength steels used for swage punches can handle being pressurized to 20,000 and up to 50,000 psi during swaging, then being pulled back while pressure is still applied, if they have at least .015 inches of thickness at the thinnest edge that is under pressure. A punch brought right to the die wall, as in a conventional boattail shape, would have zero edge thickness. It might make one bullet before the moving punch was ripped apart at the edge, leaving a ragged .015 inch margin and leaving the remains of the thin edge stuck in the bullet or pushed out as bits and pieces.

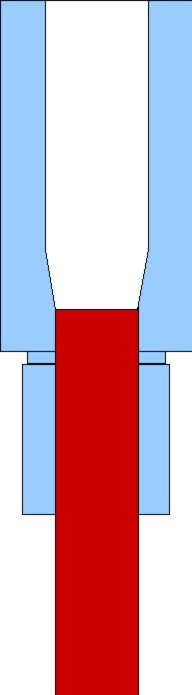

So, if a punch cavity with a thin edge can't be used due to very short life under swaging pressure, what could be used? The usual solution is a die. The RBT-2 die set made by Corbin first creates a conventional boattail shape on the closed end of the jacket, by seating lead into the jacket within the die. The die wall has the base angle machined, lapped and polished in it. Because it has this angle in the die wall, there is no thin punch edge to worry about. But the only way this can be formed on the base of the bullet is to seat the core into the jacket and expand the jacket within this die. Once the base is made, it is not easy to maintain the angle without a step in later stages. The punches which push the bullet into other dies, such as the point forming or lead tip finishing dies, would need to have at least .015 inch edge thickness. This in turn would press on the jacket and transfer some or all of that step to the bullet, depending on the pressure used.

So, if a punch cavity with a thin edge can't be used due to very short life under swaging pressure, what could be used? The usual solution is a die. The RBT-2 die set made by Corbin first creates a conventional boattail shape on the closed end of the jacket, by seating lead into the jacket within the die. The die wall has the base angle machined, lapped and polished in it. Because it has this angle in the die wall, there is no thin punch edge to worry about. But the only way this can be formed on the base of the bullet is to seat the core into the jacket and expand the jacket within this die. Once the base is made, it is not easy to maintain the angle without a step in later stages. The punches which push the bullet into other dies, such as the point forming or lead tip finishing dies, would need to have at least .015 inch edge thickness. This in turn would press on the jacket and transfer some or all of that step to the bullet, depending on the pressure used.

Corbin angles the base only for the purpose of allowing the bullet base to fit into a cavity punch in the next step, which is the creation of a consistent and precise rebated boattail. A punch is used, in a very slightly larger RBT forming die, to apply this angle in a purposeful way, using consistent pressure. From this point on, punches having the RBT cavity can be used to further push the bullet into other dies, without damage to the base or the punches. Boattailed bases can be made by using a two-part, take-apart die which has a nose cavity in one half, and a base cavity in the other. Usually this kind of die will produce a flange or ridge where the two dies come together, especially after having been used long enough to wear and produce slight misalignment. The joint expansion area is then smoothed out and reduce by passing through a reducing die. Another method that sometimes works, but is not reliable enough for Corbin to provide a standard system based upon the principle, is a two part die that has a knife-edged punch captive in the lower section.  The punch does tend to wear out, but by maintaining tightly fitted contact with the special die lower section, the punch can expand like a piston ring and stay the same diameter, less slight pressure expansion during the swaging procedure. It does not have to come out of the die and go back in again, which would rapidly wear off the knife edge. The FX-1 bullet fixer die is built in this way, to reform existing bullets. But it is not a satisfactory way to actually produce new bullets with boattails except by luck with specific jacket and core hardness, grain structure, shapes and pressures -- that is, not consistently operable over random ranges of weights and calibers. So it is not offered for that reason. But in theory at least this is one way to produce the conventional boattail without the cost of multi-stage punch press operations.

The punch does tend to wear out, but by maintaining tightly fitted contact with the special die lower section, the punch can expand like a piston ring and stay the same diameter, less slight pressure expansion during the swaging procedure. It does not have to come out of the die and go back in again, which would rapidly wear off the knife edge. The FX-1 bullet fixer die is built in this way, to reform existing bullets. But it is not a satisfactory way to actually produce new bullets with boattails except by luck with specific jacket and core hardness, grain structure, shapes and pressures -- that is, not consistently operable over random ranges of weights and calibers. So it is not offered for that reason. But in theory at least this is one way to produce the conventional boattail without the cost of multi-stage punch press operations.

However, since the RBT shape provides long tool life, lower tooling cost, more consistent release of the bullet from the muzzle, less turbulence-induced deflection of the bullet, and has only one drawback (it loads like a flat base bullet in automatic machinery), Corbin offers the Rebated Boattail design rather than the boattail. |

| Home Page | Price List | E-Mail Sales | Site Map | New Products | Q&A | Terminology |

| Retirement | Specials | Real Estate | Software | How to swage | CSW Die | CS Die |