| Home | Presses | Intro | Site Map | P.R. | Chemicals | Answers |

|

| Prices | Specials | How To | Bullets | B.Makers | Books | Classified | |

| Topics | Jackets | Terms | Training | Software | Products | Contact us |

|

|

|

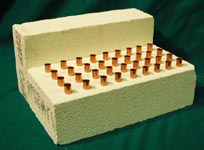

Corbin's special ceramic foam blocks can withstand up to 2,600 degress (F) and protect the work surface. Only about 800 to 1000 degrees is required for rapid melting of the lead core while the bonding flux is still present as a hot vapor, to effect perfect bonded cores and to heat treat drawn copper or gilding metal jackets for better expansion without cracking.

The ceramic blocks are not "hard" in the usual sense, but can be drilled easily with an ordinary wood drill (spade bit) or cut with a coarse-tooth hacksaw. This makes it simple to drill a pattern of 32 half inch (or smaller) holes partly through the 4-1/2 inch by 9 inch side of the block, to create a high temperature "holding tray" for bullet jackets.

The ceramic blocks are not "hard" in the usual sense, but can be drilled easily with an ordinary wood drill (spade bit) or cut with a coarse-tooth hacksaw. This makes it simple to drill a pattern of 32 half inch (or smaller) holes partly through the 4-1/2 inch by 9 inch side of the block, to create a high temperature "holding tray" for bullet jackets.

The blocks are 4.5 by 9 by 2.5 inches high. Drilling holes one inch deep into them makes an effective, easy to use holder for nearly any size or length of bullet jacket. At least 3/8 inch should be left between adjacent drill holes for strength. The block should be held firmly but not clamped directly with a c-clamp, for drilling (it may crack if compressed too firmly without a wood, rubber, or leather pad under the clamp). Click for Prices. |

Order Now!

Order Now!

|

Order from:

|

Corbin HTO-2 Heat Treatment Furnace |

| Home Page | Price List | E-Mail Sales | Site Map | New Products | Terminology | |

| Retirement | Specials | Real Estate | Software | How to swage | Classified Ads | Feedback |