| Home | Presses | Intro | Site Map | P.R. | Chemicals | Answers |

|

| Prices | Specials | How To | Bullets | B.Makers | Books | Classified | |

| Topics | Jackets | Terms | Training | Software | Products | Contact us |

| Home | Presses | Intro | Site Map | P.R. | Chemicals | Answers |

|

| Prices | Specials | How To | Bullets | B.Makers | Books | Classified | |

| Topics | Jackets | Terms | Training | Software | Products | Contact us |

| ||

S-Press |

Hydro-Press |

Mega-Mite |

|

The CSP-1H is not available, but is listed for assistance with identification of secondary (used) market items. Owners of the Hydro-Mite may still obtain service items and most parts from Corbin, subject to availability. We suggest the CHP-1 Hydro-Press as a more versatile alternative.

Tireless Production:

|

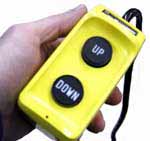

We do not suggest that most handloaders can or should become involved with explosives, tracers, or other chemical special effects, but if you are already involved and know what you are doing, this press can provide an additional margin of safety to your work. When the ram goes up and the material is compressed, you have the ability to be behind a barricade with the controls in your hand.

We do not suggest that most handloaders can or should become involved with explosives, tracers, or other chemical special effects, but if you are already involved and know what you are doing, this press can provide an additional margin of safety to your work. When the ram goes up and the material is compressed, you have the ability to be behind a barricade with the controls in your hand.

The CSP-1H can be provided with either 110-120 volt 60 Hz, 220-240 volt 60 Hz, or 240 volt 50 Hz motor of 3/4-HP, single phase. The press has a stroke emulating the full length (reloading) stroke in the regular CSP-1, but with full swaging power. It can be used for both jacket drawing and swaging, as well as reloading. When using bullet swage dies, a stop pin and positive ram travel limiter are used, so the press only moves the standard 2 inches required for -S dies and punches. Care must be taken to adjust reloading dies properly! It is possible to flatten a reloading press die if you misadjust the die position and then run the ram up under full power. Always run the ram up first and then install and adjust the die with the ram at maximum extension. The CSP-1H Hydro-Mite Press uses a high quality, industrial grade hydraulic power unit equipped with remote operation solenoid valve controls. The power unit connects to the press assembly with two flexible hydraulic lines, each of which has instant disconnect fittings (self-closing). The power unit is equipped with a power switch and thermal overload protection. It is a relatively quiet unit, such that a normal conversation can be held while it is running, and it is unlikely to bother anyone in the next room if operated at night. Unlike low-priced copies which use Ag-grade hydraulics, the Corbin Hydro-Mite is built with Industrial Grade Hydraulics with as much as 200% safety margin ratings, giving you a safe, long-lived design that will be running decades after lower quality copies have failed. Differences include the quality of cylinder seals and piston, rods and valves, and the pressure and life-expectancy of the motor and pump unit, which is a continuous duty industrial forced-air fan-cooled design. The strong, compact cylinder and standard frame mean that the Corbin Hydro-mite press fits into a smaller space and takes up less vertical room than units assembled from agricultural or automotive components (as these usually require long add-on tie rods and home-made adapters, adding to the length and reducing rigidity and strength). Click for prices |

Order from:

CORBIN

PO Box 2659

600 Industrial Circle

White City, OR 97503 USA

| Home Page | Price List | E-Mail Sales | Site Map | New Products | Auto Q&A | Terminology |

| Retirement | Specials | Real Estate | Software | How to swage | Classified Ads | Feedback |