| Home | Presses | Intro | Site Map | P.R. | Chemicals | Answers |

|

| Prices | Specials | How To | Bullets | B.Makers | Books | Classified | |

| Topics | Jackets | Terms | Training | Software | Products | Contact us |

| Home | Presses | Intro | Site Map | P.R. | Chemicals | Answers |

|

| Prices | Specials | How To | Bullets | B.Makers | Books | Classified | |

| Topics | Jackets | Terms | Training | Software | Products | Contact us |

| |

"...head and shoulders above the competition."

|

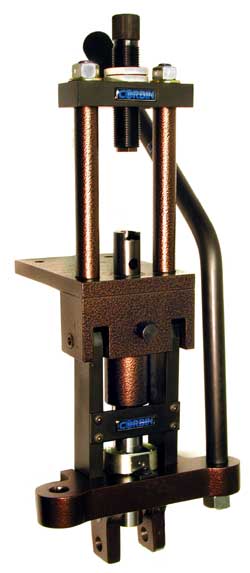

Corbin S-Presstm

Corbin S-Presstm

The S-Press is a high precision, high pressure, steel frame roller-bearing swaging and reloading press. It has become the world's most popular home swaging press, replacing the prior Series II press, and the decades of Corbin's Silver Press and early Mity Mite presses.

Corbin pioneered the aircraft-inspired torsion/compression strut, which consists of a heavy section of steel cylinder under high compression force, applied through a central rod under equal but opposite tension.

The CSP-1 press has a tough stop pin that passes completely through the ram, and is supported on both sides by the frame. The hardened steel stop pin bears against the lower end (head) of the internal swage punch, stopping it as the ram and die are moved down, which in effect pushes the internal punch and the bullet out of the die when you lower the ram. This smooth, easy ejection of the bullet is quicker than using a separate ejector or a mallet, as you would do with a reloading press swage die. It is gentle, smooth, and uses the full power of the press leverage to eject the bullet without impact shock. Instead of just getting the world's best selling swaging press with the longest history of improvements, you are also getting one of the world's most precise and accurately aligned benchrest grade reloading presses!

The head of the CSP-1 press is a thick plate of steel, precision machined, bored, and threaded for either the standard 7/8-14 tpi, or for any custom thread you wish. Different heads can be provided for obsolete dies or those which may be developed in the future.

Not only bullet swages of every caliber and type, from airgun pellets to round ball, from 0.100 caliber to 0.458, but also arbor press anvils, jacket drawing kits, tubing jacket makers, floor stands, two varieties of operating handles, quick-change punch holders, bullet reducing dies, "Saber-Tooth" dies, and much more... From the first S.A.S. Mity Mite, through the Series II, to the current S-Press, the CSP-1 model has undergone continuous improvement based on experience from the world's foremost bullet swage tool makers. Others have come and gone, leaving behind unsupported attempts at a copy. Corbin remains the only bullet swaging firm in the world with the depth of talent and serious interest to support you into the future.

Comes with a FREE reloading adapter kit, for standard RCBS type shell holders. Now included FREE is the previously optional handle retainer kit, which automatically snaps around the ram on the down stroke and keeps the handle from falling if you bump the press.

|

|

The improvement never ends...

Point forming internal punches made after 2001 have a larger diameter head with a through-hole, similar to the Corbin Hydro-Press (-H) type dies. This allows for a stop pin that passes completely through the ram, and is supported on both sides of the frame, more than doubling the strength compared to earlier presses.

Point forming internal punches made after 2001 have a larger diameter head with a through-hole, similar to the Corbin Hydro-Press (-H) type dies. This allows for a stop pin that passes completely through the ram, and is supported on both sides of the frame, more than doubling the strength compared to earlier presses.

Yet, the CSP-1 works fine with your early -M and -S dies, using the optional STOPPIN-1, shown at far right. The longer pin for the S-press is the STOPPIN2, near right. Both are available as replacement parts on www.SwageDies.com web store.

Yet, the CSP-1 works fine with your early -M and -S dies, using the optional STOPPIN-1, shown at far right. The longer pin for the S-press is the STOPPIN2, near right. Both are available as replacement parts on www.SwageDies.com web store.

A steel locking bar secures both the links to eliminate any side play and keep both of the ram link in perfect sync for smoother operation, reduced rotational torque on the ram, and longer life with higher alignment precision. It provides the aligment accuracy formerly achieved by benchrest loading dies used with arbor presses.  The S-Press now has a hidden positive locking retainer for the stop pin (the pin through the front of the press that creates automatic ejection of bullets on the down stroke) instead of the ball detent/set screw device used on the earlier models. This positive retainer holds the pin around its circumference instead of just pushing on one side, for a reliable and positive lock. You can feel it grip the pin, so the chance of pulling it out by accident is slim.

The S-Press now has a hidden positive locking retainer for the stop pin (the pin through the front of the press that creates automatic ejection of bullets on the down stroke) instead of the ball detent/set screw device used on the earlier models. This positive retainer holds the pin around its circumference instead of just pushing on one side, for a reliable and positive lock. You can feel it grip the pin, so the chance of pulling it out by accident is slim.

The S-press frame is machined entirely of steel, with no castings, and has a tensile strength in excess of 100,000 psi (compared to the largest cast frame presses advertising 40,000 to 45,000 psi maximum). All links run in bearings, as does the ram (two inch-long oil-impregnated bronze bearings support and guide the ram inside its hydraulic cylinder sleeve housing). The press comes with a reloading adapter kit at no extra cost. It can be used in a 4-inch stroke configuration for reloading, or with a 2-inch stroke for swaging, simply by moving the ram pin to a different pair of holes in the linkage. A spent primer catcher tray comes with the press. The tray slips over the ram and rides up and down with the shell holder adapter (which takes standard RCBS button shell holders). Spent primers are rolled into the tray through an angled port in the shell holder/ram extension, as is all priming residue. The S-press (catalog number CSP-1) is a hand-made, assembled and tested product with an industrial hard-chromed ram (not the soft screw stock used in most mass produced, cast frame presses). The entire press frame and handle has an electro-coated metal and polyester powder coat finish baked not just on, but actually baked into the pores of the steel, so it will look good for years to come even after hard use. The finish resists corrosion, and looks great on your loading bench, without showing grease, lube, or residue stains. |

Alignment System:

Years of development have gone into building a precision alignment system for the CSP-1 press ram and head. Both for precision reloading and for bullet making, the axial and angular alignment must be precise for best results. Most presses have two kinds of alignment error.

Years of development have gone into building a precision alignment system for the CSP-1 press ram and head. Both for precision reloading and for bullet making, the axial and angular alignment must be precise for best results. Most presses have two kinds of alignment error.

This kind of alignment error occurs when a press casting is drilled from one end, flipped, and drilled from the other. The axis of the hole for the ram may not be exactly on line with the center of the hole for the head, because of drill drift or holding variances. The ram is parallel to the head but runs off to one side of it. This kind of alignment error occurs when the drill either flexes or bends slighly in passing through the gap between the ram bore and the head, or the press casting is turned around to drill from both ends and there is an angular alignment error in the clamping. The two holes appear to be in alignment, but one or both are actually tipped slightly about the centerline. The ram runs at a slight angle to the head. These errors were corrected in Corbin presses with the following procedures, which pointed out other, smaller corrections which were hidden until the alignment precision was brought into a much closer tolerance than is possible with conventional press construction. Then, these lesser factors were identified and corrected, one by one. Many are caused by errors so small that they only become apparent when the larger issues are solved, such as the slight angle between the threaded bore of commercial nuts to their bearing surfaces, or the variance in thickness of standard washers from one side to the other. Time consuming machine work is required on every piece of hardware if these sources of uneven stress are to be eliminated. Lower cost press manufacturers simply cannot afford to take all the extra time these many steps require (and, for less demanding work, it isn't required). |

|

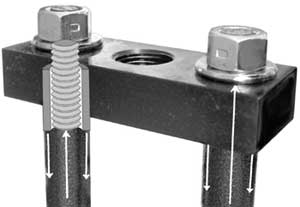

The bottoms of each of the nuts is lathe turned for flatness using a jig that maintains exact right angle to the bore of the nut. (Commonly purchased nuts usually show considerable tilt or angular misalignment between the true axis of the nut's threads, and the bearing surface of the nut, which will push the threaded rod slightly to one side as you tighten the nut.) Assembly is done with the alignment jig in place, so it could not be removed if there was any misalignment in any direction. This assures the machinist he has done it correctly: he cannot go on if the press isn't exactly aligned so his alignment tool can slide out of the press.  The support rod system is a composite design, using torsion/compression pairs instead of a simple one-piece rod. What appears to be a solid round bar of steel is actually a steel tube with a threaded steel rod inside. The heavy threaded rod screws into the base, passing through the mounting plate and into the solid steel ram block. The support rod holes are jig bored in a heavy duty milling machine, to maintain parallelism with the bore line. The torsion rods are screwed into place, and the two steel cylinders are placed over them with temporary holding nuts. The assembly is powder coated, with a baked-in polyester/copper finish, and then the holding nuts are removed.

The support rod system is a composite design, using torsion/compression pairs instead of a simple one-piece rod. What appears to be a solid round bar of steel is actually a steel tube with a threaded steel rod inside. The heavy threaded rod screws into the base, passing through the mounting plate and into the solid steel ram block. The support rod holes are jig bored in a heavy duty milling machine, to maintain parallelism with the bore line. The torsion rods are screwed into place, and the two steel cylinders are placed over them with temporary holding nuts. The assembly is powder coated, with a baked-in polyester/copper finish, and then the holding nuts are removed.

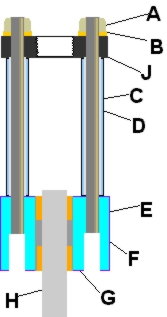

Next, a black-oxide finished steel top plate, bored on the same spacing as the base block, is slipped over the longer threaded torsion rods and rests on the top of the compression cylinders. The holes through which the rods pass are slightly larger than the rod diameter, to allow for adjustment of alignment. A precision alignment tool, which is similar to the press ram with a machined section on top that just passes through the 7/8-14 threaded hole in the top plate, is inserted in the press, and used to align the top plate.  At this point, the top plate (J) rests on the compression cylinders (C) but is not secured. Two hardened steel washers (B) are lubricated and then placed over the rods (D), resting on the top plate. Then two grade eight hardened aircraft grade hex nuts (A) are torqued down over the washers, which allow for tightening without disturbing the alignment. Each nut is torqued in turn while watching the alignment of the test rod in the press head. Any final misalignment between the press head, and the ram bore, locks the test rod so it cannot be removed. If the test rod can be slid out of the press after the nuts are torqued down, the axis of the top and bottom of the press bore must be both axially and angularly aligned.

At this point, the top plate (J) rests on the compression cylinders (C) but is not secured. Two hardened steel washers (B) are lubricated and then placed over the rods (D), resting on the top plate. Then two grade eight hardened aircraft grade hex nuts (A) are torqued down over the washers, which allow for tightening without disturbing the alignment. Each nut is torqued in turn while watching the alignment of the test rod in the press head. Any final misalignment between the press head, and the ram bore, locks the test rod so it cannot be removed. If the test rod can be slid out of the press after the nuts are torqued down, the axis of the top and bottom of the press bore must be both axially and angularly aligned.

The torsion/compression support design keeps constant tension on the rod and cylinder, so that side torque has less bending movement than it would on a similar diameter of solid rod. The links are individually fitted with four sets of Torrington roller needle bearings running on hardened and ground pins. The bearings are covered by the toggle arms at one end and the press block at the other, so they are not apparent unless the press links are removed. Because many of features of the CSP-1 press are hidden, greater appreciation of the work that goes into building it comes from comparing its smooth operation, high strength and power, and extreme precision, with the typical over-the-counter retail presses. The net result of these detailed efforts is a tool orders of magnitude more accurate than those which must be built to sell through two or three levels of distribution markups to the end user. If the standard rule of thumb is that retail pricing is about 4 times cost of manufacture, to allow for profit for manufacturer, jobber, distributor, and dealer, it means a $100 press has about $25 worth of parts and labor in it at the factory door. Obviously, one can use better materials, design and construction when the end price does not contain distribution markups. |

|

|

CBP-S Floor Stand

CBP-S Floor Stand

Self-supporting heavy duty steel floor stand with mounting bolt holes for either the CSP-1 or CSP-2 press. Tough wood fiber deck puts your own weight into the system so you are the anchor; no holes in the floor, no braces required for solid reliable operation. (Truck shipment only, 150-lbs). One-inch thick top plate is tapped for both the S-Press and the Mega Mite press (click photo for hole pattern layout). Adjustable height for convenient, easier operation. Set to suit your needs! |

FPH-QC-S Quick Change Punch Holder. Rapidly change punches when using very long bullets, copper tubing, or jackets. Slip the punch in and out sideways to load and unload components instead of screwing the holder up and down each time. (more info...)

FPH-QC-S Quick Change Punch Holder. Rapidly change punches when using very long bullets, copper tubing, or jackets. Slip the punch in and out sideways to load and unload components instead of screwing the holder up and down each time. (more info...)

|

CSP-A Anvils. Use the CSP-1 as a high powered arbor press with these

two hardened steel screw-in anvil heads. One fits the floating punch holder, and the other fits the press ram, providing two flat surfaces to push pins, bearings, gun sights, operate non-threaded benchrest dies or mini-broaching tools, crack walnuts (whatever). The usefulness of the press extends to other fields outside handloading, which can be an advantage when importing (the customs declaration can specify "precision metal forming" press and avoid potential misunderstandings about "reloading requipment"). (more info...)

CSP-A Anvils. Use the CSP-1 as a high powered arbor press with these

two hardened steel screw-in anvil heads. One fits the floating punch holder, and the other fits the press ram, providing two flat surfaces to push pins, bearings, gun sights, operate non-threaded benchrest dies or mini-broaching tools, crack walnuts (whatever). The usefulness of the press extends to other fields outside handloading, which can be an advantage when importing (the customs declaration can specify "precision metal forming" press and avoid potential misunderstandings about "reloading requipment"). (more info...)

|

CSP-C Handle Retainer Assembly This easy-to-install accessory for the Series II holds the press handle securely without in any way interferring with normal operation. (The current production S-Press comes with a built-in retainer, so this accessory is not required.) The spring clip snaps around the hardened ram on the down stroke, holding the handle in the vertical position so it cannot accidently fall while you are working around the press. Worth its weight in the fingers you don't pinch and the heads that are not bonked when you crawl around on the floor looking for that dropped primer or bullet. (More info...)

CSP-C Handle Retainer Assembly This easy-to-install accessory for the Series II holds the press handle securely without in any way interferring with normal operation. (The current production S-Press comes with a built-in retainer, so this accessory is not required.) The spring clip snaps around the hardened ram on the down stroke, holding the handle in the vertical position so it cannot accidently fall while you are working around the press. Worth its weight in the fingers you don't pinch and the heads that are not bonked when you crawl around on the floor looking for that dropped primer or bullet. (More info...)

|

FPH-1-S Floating Punch Holder. One comes with the press, but you may

find a spare useful to set up and quickly change to another operation, leaving the punch in place and changing the holder.

FPH-1-S Floating Punch Holder. One comes with the press, but you may

find a spare useful to set up and quickly change to another operation, leaving the punch in place and changing the holder.

While we're at it, the primer tray (CSP-T) and the reloading adapter (CSP-R) come with the press as well, but are available as replacements or spares. The primer tray fits over the ram and rides up and down with it, catching spent primers and primer residue that roll out of the angled ejection port on the reloading adapter. The reloading adapter (CSP-A) is a combined button shell holder adapter and ram extension with a primer port on the side. It takes standard RCBS-type button shell holders, securing them with a ball bearing detent. |

CSP-1LH Long Handle Option A standard 18-inch handle comes with the press, but you can add the 24-inch long handle for those special situations where extra leverage comes in handy.

CSP-1LH Long Handle Option A standard 18-inch handle comes with the press, but you can add the 24-inch long handle for those special situations where extra leverage comes in handy.

The long handle requires more "reach" than is necessary for most operations, so you will probably want to keep the standard handle. It doesn't require quite so much stretching as the long handle, but when you need it, the additional power is welcome! The CSP-1 comes standard with the CSP-1SH standard handle, but this handle is also available as a replacement item. Roller side-bar handles similar to those used on the CSP-2 Mega Mite can be provided on special order. |

CSP-1RH Roller Side-Bar Handle Option You can add a special heavy duty roller side-bar handle just like the big Mega Mite press uses. The roller side-bar handle lets you grip the handle with your hand on the horizontal plane, rather than vertical. The large diameter steel roller "grip" turns as you move the handle, so that your grip does not cause any friction against your skin. Some bullet makers find this more comfortable than the vertical expanded neoprene rubber grip.

CSP-1RH Roller Side-Bar Handle Option You can add a special heavy duty roller side-bar handle just like the big Mega Mite press uses. The roller side-bar handle lets you grip the handle with your hand on the horizontal plane, rather than vertical. The large diameter steel roller "grip" turns as you move the handle, so that your grip does not cause any friction against your skin. Some bullet makers find this more comfortable than the vertical expanded neoprene rubber grip.

The CSP-1 comes standard with the CSP-1SH standard handle, but the roller handle is available as a replacement item. Roller side-bar handles (similar to those used on the CSP-2 Mega Mite) are not a standard "listed" item but can be special ordered. They are the same price as the CSP-2-SH which is the roller sidebar handle for the Mega-Mite, and in fact is the same except for the diameter of the threads attaching it to the press toggle. |

For prices, see the current Price List.

For prices, see the current Price List.

The CSP-1 S-Press may be ordered on-line, from Corbin's secure server. Just click the padlock icon on Corbin's home page. Prior references to the Series II press apply to the S-Press, which is interchangeable except that the S-press uses the stronger ejection system.

The CSP-1 S-Press may be ordered on-line, from Corbin's secure server. Just click the padlock icon on Corbin's home page. Prior references to the Series II press apply to the S-Press, which is interchangeable except that the S-press uses the stronger ejection system.

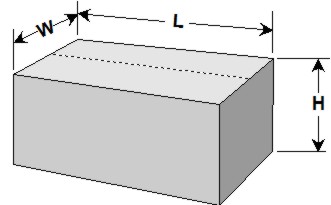

Packaging information: Shipping weight 22 lbs. Carton size: Length = 19 in, Width = 11 in, Height = 9 in. |

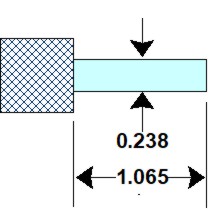

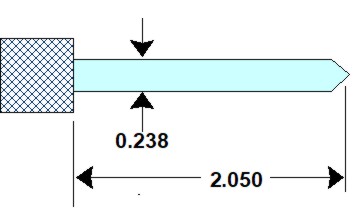

Mounting pattern for both CSP-1 and CSP-2 presses (left). The CSP-1 S-Press mounting holes are the three inside; the CSP-2 Mega Mite uses the three larger outside holes.

CSP-1 Ram Dimensions

CORBIN

|

| Home Page | Price List | E-Mail Sales | Site Map | New Products | Q&A | Terminology |

| Retirement | Specials | Real Estate | Software | How to swage | Classified Ads | Feedback |